Vertical Broaching Machines

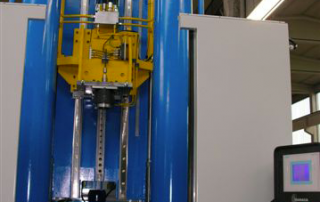

Classical pull type broaching machines with hydraulic or electromechanical drive systems.

The machines can be equipped with one or more stations with part loading and unloading with alternating or rotary tables for fast cycle times thanks to the tool’s return during the load/unload cycle.

Optionally, the machine can be supplied with semi-automatic broach changeover and traction sleeves.

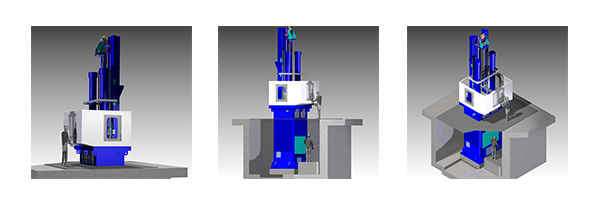

The machine is normally installed in a pit or flush with the floor using platforms.

Vertical Broaching Machines

Classical pull type broaching machines with hydraulic or electromechanical drive systems.

The machines can be equipped with one or more stations with part loading and unloading with alternating or rotary tables for fast cycle times thanks to the tool’s return during the load/unload cycle.

Optionally, the machine can be supplied with semi-automatic broach changeover and traction sleeves.

The machine is normally installed in a pit or flush with the floor using platforms.

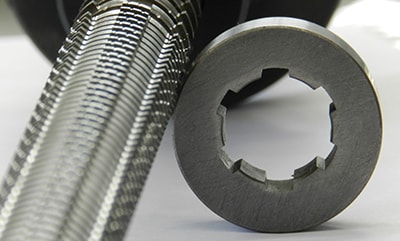

Technical Characteristics

- Monolithic structure made of cast iron to ensure precision cutting with vibration absorption during machining.

- Available with hydraulic or electromechanical drive systems.

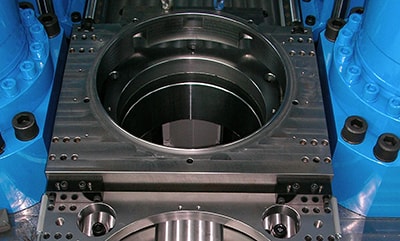

- Can be used with one or more work stations.

- Suited to various lengths of broaches.

- Suited both for emulsions and full oil.

- PLC Siemens if hydraulic drive system.

- CNC Fanuc if electromechanical drive system.

- Chip conveyor.

- Double filtering action external purification system with fabric and magnetic disks.

The machine is normally installed in a pit or flush with the floor using platforms..

| CHARACTERISTICS | HYDRAULIC | ELECTROMECHANICAL |

|---|---|---|

|

Cutting force [ton]

|

from 4 to 230 | from 4 to 70 |

|

Tool stroke[mm]

|

from 1000 to 3000 | from 1000 to 3000 |

|

Table dimensions[mm]

|

from 250 to 800 | from 250 to 500 |