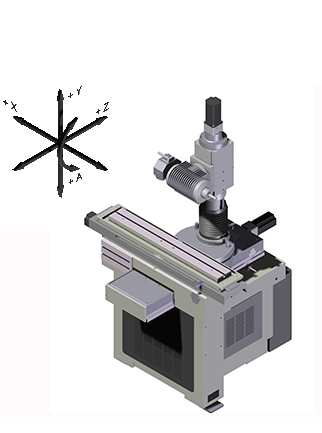

GRINDING MACHINE SMART PRO 500

The universal grinding machine Nesi, with 1 – 4 controlled axes, is the expression of Nesi’s continuous technological research.

To obtain design targets, rail with rolling friction have been installed on the longitudinal axis (working table) and transverse axis (carriage support head), with the dual benefit of smoother travel combined with increased working load.

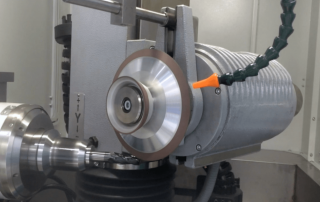

The electric spindle has a wide range of speeds, thus allowing accurate calibration for the best cutting result.

GRINDING MACHINE

SMART PRO 500

The universal grinding machine Nesi, with 1 – 4 controlled axes, is the expression of Nesi’s continuous technological research.

To obtain design targets, rail with rolling friction have been installed on the longitudinal axis (working table) and transverse axis (carriage support head), with the dual benefit of smoother travel combined with increased working load.

The electric spindle has a wide range of speeds, thus allowing accurate calibration for the best cutting result.

Processing typologies

SMART PRO 500

The grinding machine SMART PRO 500 has 1-4 controlled axes. Thanks to the high performances of the machine, it is possible to grind nearly every kind of tool.

The monolithic structure made of cast iron ensures precision cutting with vibration absorption during machining.

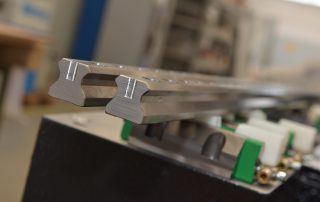

Customized machine

Thanks to a double 3D probe the machine is able to automatically calculte the tool profile and generate the part-program.

The machine developed by Cabe’s team of engineers allows the sharpening and construction of straight and curved blades with unknown geometric profile.

Highlights

Technical characteristics

- Fanuc control.

- Brushless and torque motors (A) for high dynamic range of operations. High precision positioning on linear and rotative axes.

- The longitudinal axis (working table) and the transversal axis (carriage support head) have rail with rolling friction.

- Linear axis with re-circulation ball screws (grindind and preload) to reach high preci- sion.

- Driving axis A with technology“directdrive” for precision positioning.

- All surfaces of support and contact are grinded.

- Positioning system on the axes with optical lines and high resolution encoder directly connected to the operating parts.

- Electric spindle with a wide range of rotation speed for a precise calibration and to reach better cutting conditions.

- Integral structure with front access to load and unload the pieces, side door for practi- cal setup and maintenance.

- Oil mist reduced by centrifugal technology.

- Lubricant and coolant fluid purifiers available for every type of application.

- Automatic part loading/unloading.

SIMULTANEOUS MOVEMENT OF THE CN AXES: Tools grinding and grinding of tools or pieces with complex geometric shapes like cylindrical spiral or conical spiral.

| CONFIGURATIONS | |||

|---|---|---|---|

| 2 AXES CN | XY | XZ | XA |

| 3 AXES CN | XYZ | XYA | XZA |

| 4 AXES CN | XYZA |

| CHARACTERISTICS | |

|---|---|

|

Longitudinal X axis – piece-holder table

|

|

|

Longitudinal useful stroke [mm]

|

500 |

|

Piece-holder table length [mm]

|

970 |

|

Piece-holder table width [mm]

|

120 |

|

Piece-holder table inclination on horizontal plane, micro-metric

|

±45°, ±12°

|

|

Transverse Z axis – head-carriage

|

|

|

Transverse useful stroke [mm]

|

270 |

|

Vertical Y axis – wheel centre head

|

|

|

Vertical useful stroke [mm]

|

230 |

|

Vertical stroke of wheel centre spindle on sliding head [mm]

|

140 |

|

Overall useful stroke [mm]

|

370 |

|

Planetary base orientation on horizontal plane, radius

|

±180°, 90 mm |

|

Wheel centre head orientation on horizontal plane

|

±180° |

|

Rotating A axis – piece holder head

|

|

|

Toolholder

|

ISO 50 DIN 2080 |

|

Speed of axes movement

|

X =1÷8m/min

Y =1÷5m/min Z =1÷5m/min A =1÷700Rpm |

|

On-board machine power [kW]

|

8 |

|

Width x Depth x Height [mm]

|

Depending on the model |

|

Overall weight [kg]

|

Depending on the model |