Slotting Machine

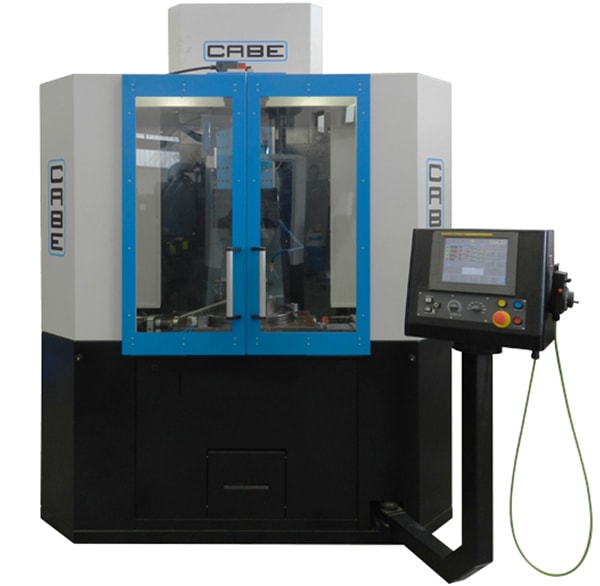

ST2 CNC

A modern and technological range characterized by 2 controlled axes and different stroke of the tool.

Comes as standard with the innovative tool-holder block with high repeatability thanks to which the tools are always positioned at the centre of the hole.

The FANUC 0i-MF control with intuitive graphical and customized interface allows the programming of gradual incremental feeds.

Slotting Machine

ST2 CNC

A modern and technological range characterized by 2 controlled axes and different stroke of the tool.

Comes as standard with the innovative tool-holder block with high repeatability thanks to which the tools are always positioned at the centre of the hole.

The FANUC 0i-MF control with intuitive graphical and customized interface allows the programming of gradual incremental feeds.

Highlights

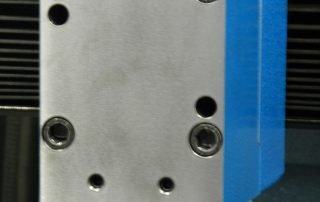

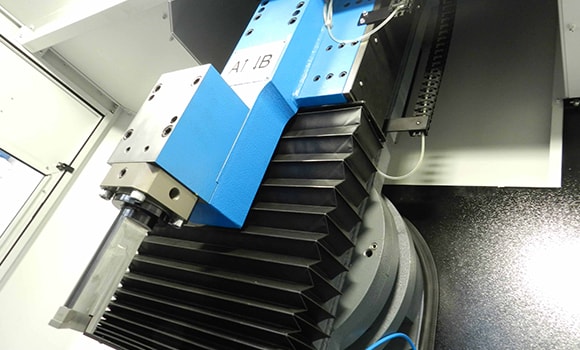

Tool Holder Block

The innovative tool holder with high repeatability guarantees that the tools are always at the centre of the hole. Combined with the tool holder, the “VCT” system, virtual tool change, allows two processes with different tools without having to stop the machine to make the change.

Fanuc control and motors

The control panel and the motor are FANUC. Cabe internally develops all the software programs in collaboration with Fanuc. We customize and verify each program directly on the machine. The Fanuc software allows programming up to now impossible to obtain, flexibility and ease of use.

Technical Characteristics

- CFANUC control, 0i-MF touch screen 10.4” model.

- Controlled swivel pieceholder table (C axis).

- Automatic disconnection of the tool during ascent phase.

- Minimal tool cooling system (alternatively, neat oil on request).

- Models with manual swivel table: divider disk.

- The controlled axes are driven by brushless motors and managed directly by the control; the movement of the controlled axes in manual mode is ensured by a remote control handwheel.

- Preloaded rectified command ball recirculation screws.

- The linear axes slide on recirculating roller guides to ensure dynamicity and precision of the movements, preloaded with centralized forced lubrication.

- Tool holder with high repeatability, patented Cabe: with this system the tools are always at the centre of the hole. Functions only with the line of Cabe tools.

- Practical and removable chip collection tank, located below the table.

- Safety around the illuminated work area is guaranteed by practical guards (2 doors) that at the same time facilitate the positioning of the pieces and prevent accidents.

- Service keys and user manual supplied.

- ”V” universal tool holder block.

- Tower signaling machine status.

- ”Fine” adjustment of the tilting head with handwheel.

- Pneumatic air blow kit for cleaning blind holes.

- Visualisation on display of the manual axes.

- Automatic chip conveyor: if present, the maximum workpiece length for machning is reduced.

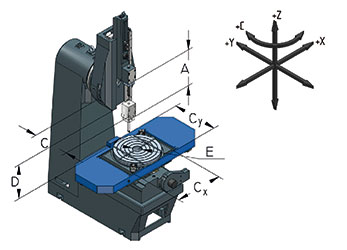

| CHARACTERISTICS | DIMENSIONS | 410 | 610 |

|---|---|---|---|

| ZY | ZY | ||

|

Settable stroke of tool [mm]

|

A | 0-575 according to Ø piece | 0-820 according to Ø piece |

| Distance between tool holder and column [mm] | C | 470 | 550 |

| Center table hole diameter [mm] | E | Ø 100 | Ø 110 |

| Strokes of the table [mm] | Cx x Cy | 410×320 | 550×460 |

| Motor / brake power [kW] | 6.5 | 9.9 | |

| Adjustable work speed [mm/min.] | 0-15.000 | 0-15.000 | |

| Maximum workpiece length for machining [mm] | Ø 95×1200 | Ø 100×1500 | |

| Power supply | 400V-50Hz-3fase | 400V-50Hz-3fase | |

| Approx. net weight [Kg] | 2400 | 5000 | |

| Machine dimensions LxWxH [mm] | 2000x2050x2620 | 2840x2650x3504 | |

| WITH RECTANGULAR TABLE | |||

| Distance underhead/rectangular table [mm] | D | 470 | 670 |

| Size of rectangular partholder table [mm] | 710×495 | 710×660 | |

| WITH SWIVEL TABLE | |||

| Distance underhead/swivel table [mm] | D | 420 | 620 |

| Diameter of swivel table [mm] | Ø 500 | Ø 600 |