GRINDING MACHINES

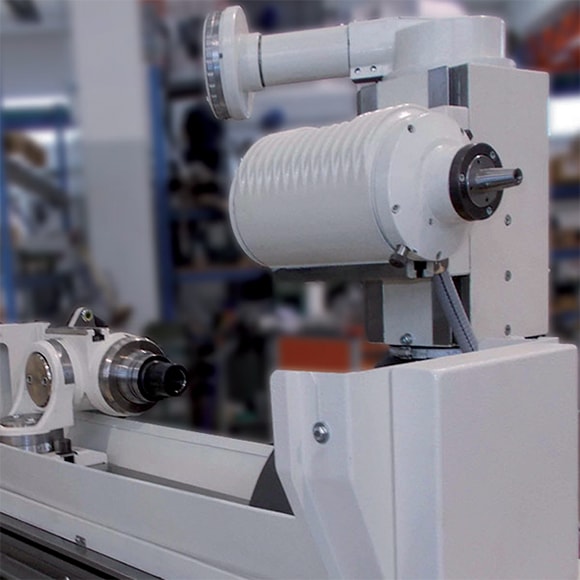

A full range of manual and CNC grinding machines. The machines can be supplied with manual or electronic axis control, or a combination of the two.

Among the first in the world to have designed and manufactured CNC grinding machines, Nesi has more than 60 years of experience in the field. The quality of the product and the team’s experience have made Nesi the first choice for grinding machines worldwide.

Today the team of engineers develops machines that meet the needs of the future. The machines are being continually improved both technologically and in terms of performance.

RANGE OF GRINDING MACHINES

A complete range of manual and CNC grinding machines with 1-4 controlled axes.

Types of processing

HIGHLIGHTS

ACCESSORIES

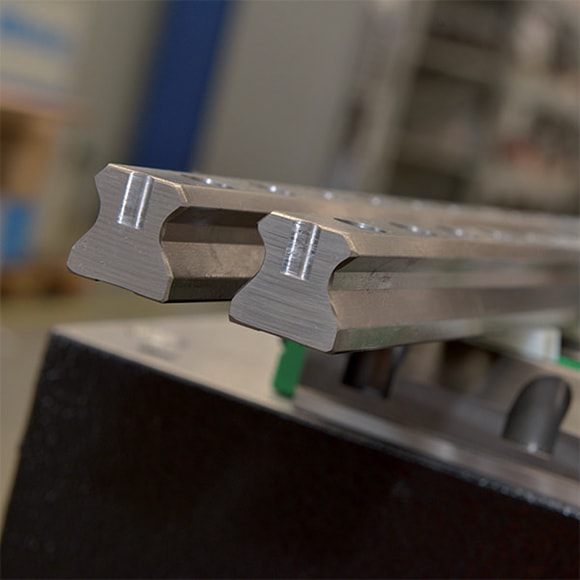

A vast range of accessories is available for all the Nesi machines, both manual and CNC. They are intended to increase the machines’ flexibility and allow the user to configure them in order to suit special requirements.

Any machining problem can be resolved with the many optional tools or with tailor-made accessories and variants. The Combitek accessory, developed by Nesi, is a semi-automatic indexing sharpening head that, in one single unit, provides a full spectrum sharpening solution.